Facilities

We give the best people the latest equipment so we can create quality products for our clients.

-

8,000m2

Factory space

-

25

Skilled

Fabricators -

2

Fabrication

Plants

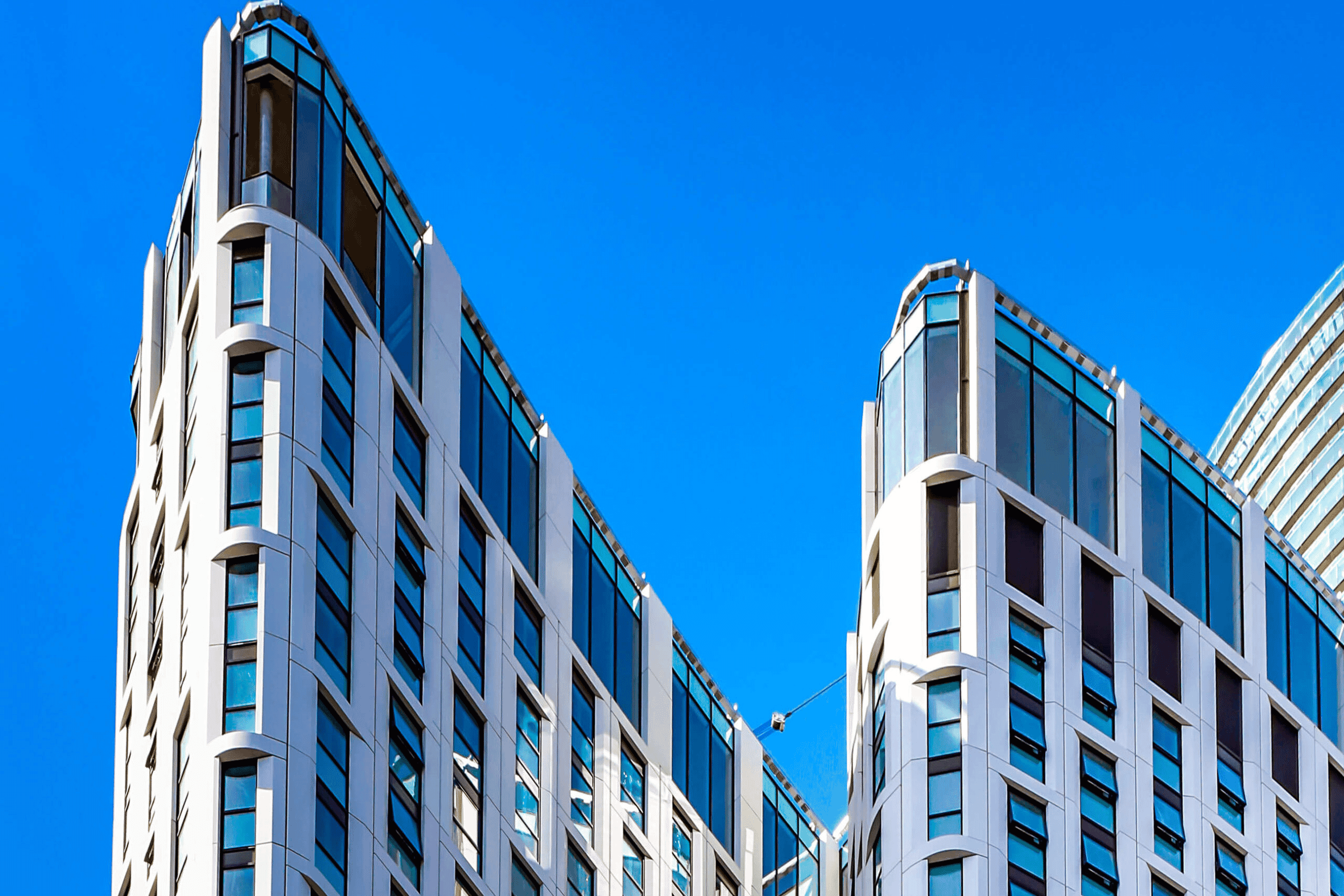

Southam Factory, Warwickshire

Situated at our Head Office, our Southam Factory is the largest of our two fabrication facilities and has seen significant investment to improve capacity and quality for our clients.

-

![]() 5,000m2 Factory Space

5,000m2 Factory Space

-

![]() 3 Brand new machines AF500, AF310

and a PDG E-Cut 650

3 Brand new machines AF500, AF310

and a PDG E-Cut 650

-

![]() 25 Skilled Fabricators

25 Skilled Fabricators

-

![]() Senator House, Bourne End, Southam CV47 0NA

Senator House, Bourne End, Southam CV47 0NA

Crown Unitised Factory

Our Crown Unitised Factory in Gloucestershire allows us to fabricate our unitised curtain walling in a controlled environment, leading to better quality and faster install times on site.

-

![]() 3,000m2 Factory Space

3,000m2 Factory Space

-

![]() Unitised Line

Unitised Line

-

![]() New Schuco AF450 CNC

New Schuco AF450 CNC

-

![]() 21 Skilled Fabricators

21 Skilled Fabricators

At Alumet, we continue to invest in the future of our business so our clients can continue to trust us.

As the industry continues to advance, we are committed to investing in our machinery and our teams of fabricators. We have recently taken delivery onf the latest Schüco machines, allowing us to perform more efficiently for our clients whilst keeping the same high quality on which we have built our reputation.